Blog

Top 10 Tips for Choosing the Right Wire Harness Equipment for Your Projects

In the intricate world of manufacturing and assembly, selecting the right wire harness equipment is crucial for ensuring efficiency and reliability in projects. As the industry evolves, the demand for high-quality components that can withstand diverse operational conditions increases. According to industry expert John Smith, a leading figure in wire harness technology, “Choosing the right wire harness equipment is not just about functionality; it’s about compatibility with your project’s specific needs.” This sentiment underscores the importance of careful consideration and planning in the selection process.

When embarking on a project that requires wire harness equipment, understanding the various options available and their respective benefits is vital. With numerous configurations and technologies on the market, professionals must assess factors such as durability, flexibility, and ease of installation. Implementing best practices in selecting the right equipment can significantly impact the overall success of the project, influencing both performance and longevity. By exploring essential tips and insights, individuals can equip themselves with the knowledge necessary to make informed decisions that align with their project goals.

Understanding Wire Harness Basics: Key Components and Terminology

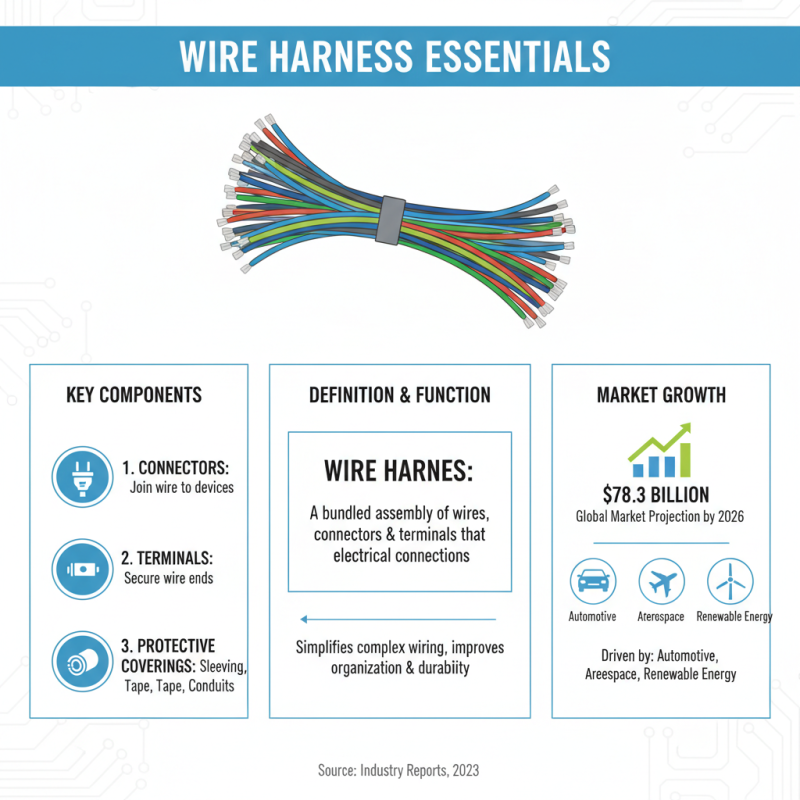

When embarking on a project that involves wire harnesses, understanding the key components and terminology is essential for successful implementation. A wire harness typically consists of multiple wires bundled together with connectors, terminals, and protective coverings, which help streamline the electrical connections across various devices and systems. Industry reports indicate that the global wire harness market is projected to reach approximately $78.3 billion by 2026, showcasing significant growth driven by sectors such as automotive, aerospace, and renewable energy.

Familiarity with wire harness terminology can also enhance your project efficiency. For instance, understanding terms such as 'grommets' (used to protect wires from abrasion), 'strain relief' (which ensures wires are secured and minimize stress at connection points), and 'pin count' (indicating the number of electrical connections in a socket) can vastly improve your selection process. Furthermore, awareness of the differences between shielded and unshielded harnesses can guide your choice based on the specific electromagnetic interference (EMI) requirements of your application. According to recent analyses, investing in high-quality wire harness components can result in up to a 30% decrease in failure rates, underscoring the importance of making informed decisions in your project.

Assessing Your Project Needs: Custom vs. Standard Wire Harness Solutions

When embarking on any project requiring wire harnesses, it's crucial to thoroughly assess your specific needs, particularly when it comes to choosing between custom and standard wire harness solutions. According to a report by Allied Market Research, the global wire harness market is projected to reach approximately $70 billion by 2027, indicating significant growth influenced by industry demands. This growth emphasizes the importance of tailoring solutions to fit unique project requirements effectively.

Custom wire harnesses are often favored in applications where precision and flexibility are paramount. They offer the advantage of being designed specifically for the dimensions, electrical specifications, and environmental conditions of a particular project. A study conducted by Grand View Research shows that custom wire harnesses can enhance performance by up to 30% in specialized applications, such as aerospace or medical devices, where standard solutions might fall short. However, for projects with more conventional specifications or where cost efficiency is critical, standard wire harnesses can provide a reliable and budget-friendly alternative. These solutions are typically quicker to procure and can still meet the necessary benchmarks for many industrial applications.

In conclusion, weighing the balance between custom and standard wire harness solutions is essential for achieving optimal results in your projects. The decision should be guided by a careful assessment of project requirements, anticipated performance levels, and budget constraints, ensuring that the chosen solution aligns with the intended application and operational demands.

Evaluating Connector Options: Types and Their Industry Applications

When selecting wire harness equipment, one of the most critical considerations involves the types of connectors available and their respective applications across various industries. Connectors serve as the bridge for establishing connections between wiring and devices, ensuring both electrical continuity and signal integrity. Different types of connectors are designed to meet specific application requirements, and understanding these can significantly streamline project execution.

For instance, environmental connectors are crafted to provide protection against moisture, dust, and extreme temperatures, making them suitable for automotive and aerospace applications where durability is paramount.

Conversely, terminal block connectors allow for easy wiring and maintenance in industrial settings by allowing multiple wires to connect securely while simplifying the circuit assembly process. Additionally, circular connectors are utilized in telecommunications and military applications for their compact design and ability to handle a range of electrical signals, thus demonstrating the importance of selecting the right connector type tailored to the project’s needs.

By thoughtfully evaluating the options available, project managers can enhance reliability and performance in their wire harness systems.

Material Selection: Balancing Cost, Durability, and Performance

When selecting wire harness equipment for your projects, material selection plays a crucial role in balancing cost, durability, and performance. A report by Freedonia Group indicates that the global wire and cable market is projected to reach $229 billion by 2026, driven by emerging technologies and increased demand for advanced electrical systems. This growth underscores the importance of choosing materials that not only meet budgetary constraints but also fulfill the performance requirements of specific applications.

Cost-effective materials, such as PVC, are popular due to their affordability and decent insulating properties. However, they may not withstand harsh environmental conditions as effectively as more durable options like thermoplastic elastomers (TPE) or cross-linked polyethylene (XLPE). According to a recent study, attributes like temperature resilience and abrasion resistance can significantly impact a wire harness's lifespan, emphasizing the need for careful material evaluation based on the operational environment. A well-informed choice ensures that the final product remains reliable and efficient while minimizing long-term costs associated with maintenance and replacements, thereby enhancing the overall project outcome.

Top 10 Tips for Choosing the Right Wire Harness Equipment for Your Projects - Material Selection: Balancing Cost, Durability, and Performance

| Material Type | Cost (per unit) | Durability Rating (1-10) | Performance Characteristics |

|---|---|---|---|

| PVC | $0.10 | 7 | Good insulation, moisture resistant |

| XLPE | $0.15 | 9 | High thermal resistance, low moisture absorption |

| Teflon | $0.50 | 10 | Excellent chemical resistance, high temperature tolerance |

| Rubber | $0.20 | 8 | Flexible, good shock absorption |

| Polyurethane | $0.30 | 9 | Abrasion resistant, resilient |

| Silicone | $0.40 | 8 | Flexible at low temperatures, good electrical insulation |

Testing and Certification: Ensuring Compliance with Industry Standards

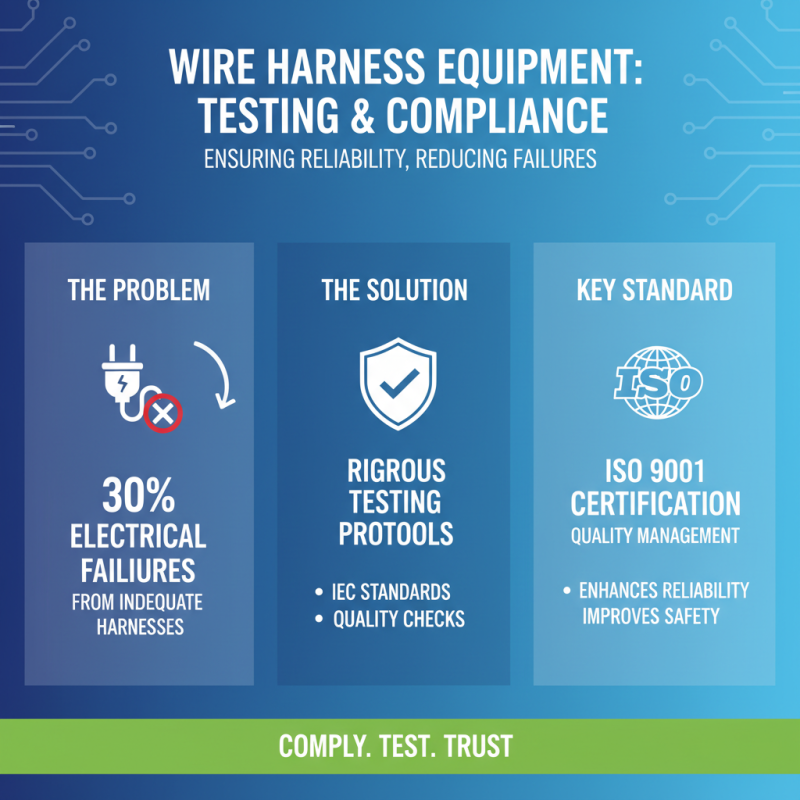

When selecting wire harness equipment for your projects, testing and certification play a crucial role in ensuring compliance with industry standards. According to the International Electrotechnical Commission (IEC), nearly 30% of electrical failures in devices can be traced back to inadequate wire harness performance. Therefore, adhering to rigorous testing protocols is essential. Compliance with relevant standards such as the ISO 9001, which focuses on quality management systems, can enhance product reliability and safety.

One key tip when choosing wire harness equipment is to ensure that all components have been subjected to third-party testing. Look for certifications from recognized bodies, which can provide assurance that the materials and construction techniques meet industry requirements. Another important consideration is to verify that the equipment undergoes regular audits and inspections to maintain its compliance status. This ongoing commitment to quality testing can significantly mitigate the risk of costly failures.

Additionally, consider the environment in which the wire harness will operate. For instance, components exposed to extreme temperatures or corrosive substances need specialized testing to guarantee performance stability. Collaborating with suppliers who emphasize a solid quality assurance process can make a substantial difference in the overall success of your projects. By prioritizing testing and certification, you not only enhance the quality of your wire harnesses but also foster trust among stakeholders and end-users alike.

Related Posts

-

Revolutionizing Connectivity: The Future of Wire Harness Solutions for Emerging Technologies

-

Unmatched Quality in Chinese Manufacturing of Wire Harness Solutions Now Gaining Global Popularity

-

How to Choose the Best Wire Harness Manufacturing Solutions for Your Needs

-

Exploring Innovative Harness Wire Alternatives for Enhanced Connectivity Solutions

-

Innovative Techniques for Streamlined Wire Harness Production

-

Top Strategies for Optimizing Wire Assembly Processes for Maximum Efficiency

Toll Free: (888) 802-2505

Phone: (256) 845-1255 or (256) 845-4493

Fax: (256) 845-1321 or (256) 845-4468

© 2025 Heritage Wire Harness, LLC