Blog

Unlocking Efficiency: How Harness Solutions Can Boost Productivity by 30% in Manufacturing

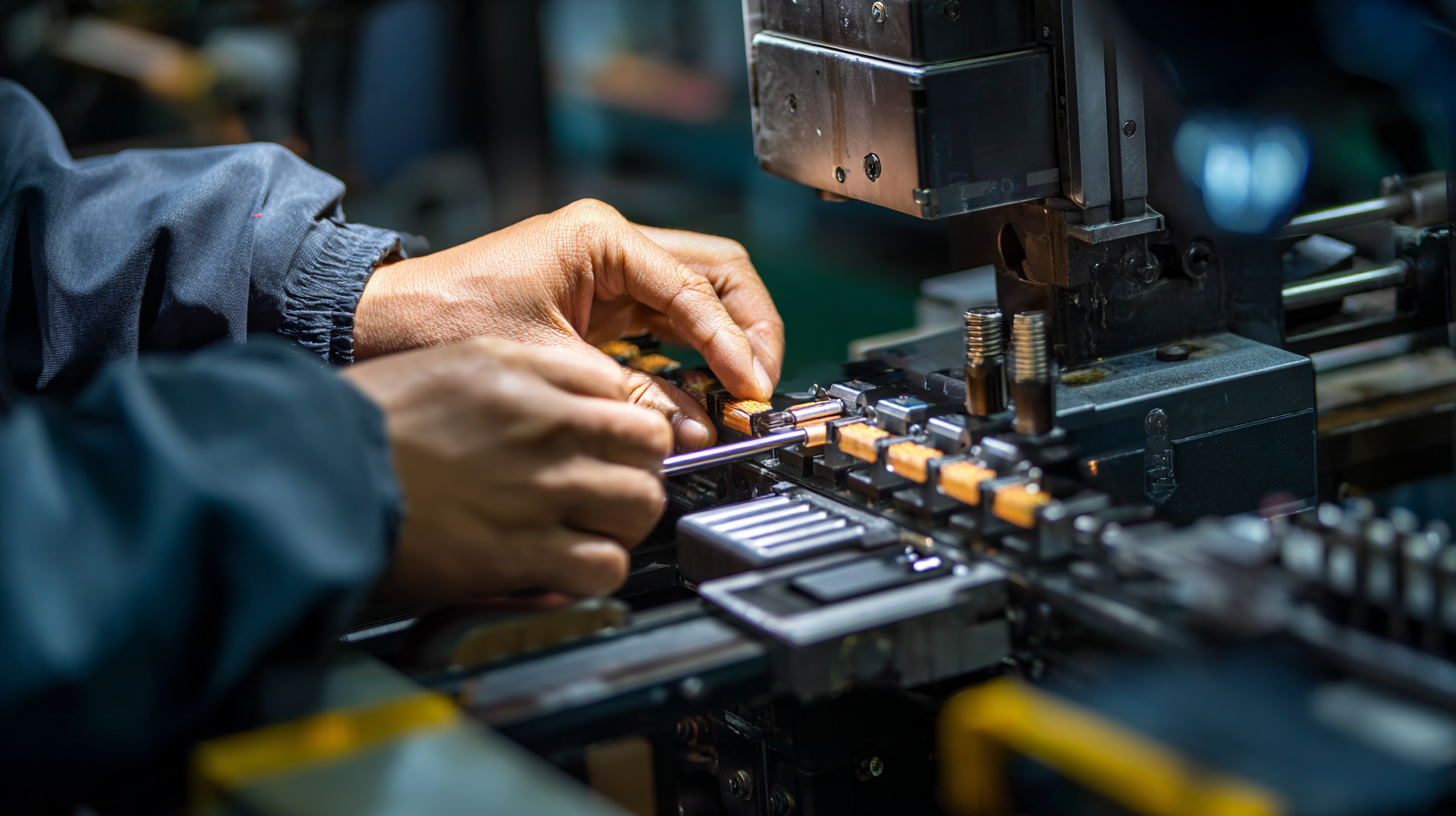

In an era where efficiency is paramount, the integration of harness solutions has emerged as a game-changer in the manufacturing sector. As industries face mounting pressures to optimize productivity and enhance operational workflows, the need for innovative strategies becomes increasingly critical. Harness solutions, which encompass advanced technologies and streamlined processes, have the potential to elevate manufacturing output by an astonishing 30%. This article will explore practical methodologies for implementing these solutions effectively, helping manufacturers to not only meet but exceed their productivity goals. By leveraging harness solutions, organizations can unlock new levels of efficiency, driving growth and competitiveness in a rapidly evolving market. As we delve into the specifics of how to utilize these solutions, the roadmap to transforming manufacturing practices will become clear, setting the stage for enhanced performance and sustainable success.

Identifying Key Inefficiencies in Manufacturing Processes

In the competitive landscape of manufacturing, identifying key inefficiencies is crucial for optimizing productivity. Many manufacturing processes are plagued by bottlenecks, redundant workflows, and outdated technology, which collectively contribute to lost time and resources. By conducting a thorough analysis of production lines, companies can pinpoint specific areas where delays and waste occur, often uncovering issues that are invisible in day-to-day operations. Techniques such as value stream mapping and performance metrics can provide insights into problem areas, allowing manufacturers to target their improvement efforts effectively.

Once inefficiencies are identified, implementing tailored solutions can lead to significant gains in productivity. For instance, integrating advanced automation systems can streamline repetitive tasks, while data analytics can enhance decision-making processes by providing real-time insights. Additionally, fostering a culture of continuous improvement encourages employees at all levels to share ideas and suggest changes that can further reduce waste. As manufacturers prioritize tackling these inefficiencies, they not only boost operational performance but also position themselves better to meet market demands and increase their overall output by 30% or more.

Implementing Harness Solutions for Streamlined Operations

Implementing Harness Solutions for Streamlined Operations

In the competitive landscape of manufacturing, streamlining operations is essential for maintaining efficiency and productivity.

Harness Solutions provides an innovative approach to optimizing workflows and reducing waste.

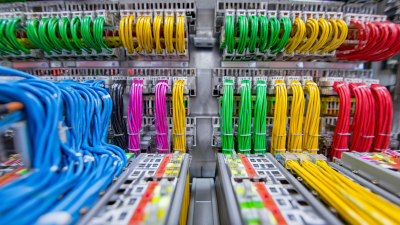

By automating repetitive tasks and integrating advanced data analytics, these solutions enable manufacturers to identify bottlenecks and enhance resource allocation.

As a result, teams can focus their efforts on high-value activities, significantly improving overall efficiency.

Moreover, the adaptability of Harness Solutions allows for seamless integration with existing systems, minimizing disruption during the transition phase.

Training employees to utilize these tools effectively further maximizes their potential, fostering a culture of continuous improvement.

As real-time insights become readily available, manufacturers can make informed decisions that lead to faster response times and enhanced customer satisfaction.

Ultimately, implementing Harness Solutions goes beyond simply increasing productivity; it creates a resilient manufacturing environment capable of thriving amidst changing market demands.

Moreover, the adaptability of Harness Solutions allows for seamless integration with existing systems, minimizing disruption during the transition phase.

Training employees to utilize these tools effectively further maximizes their potential, fostering a culture of continuous improvement.

As real-time insights become readily available, manufacturers can make informed decisions that lead to faster response times and enhanced customer satisfaction.

Ultimately, implementing Harness Solutions goes beyond simply increasing productivity; it creates a resilient manufacturing environment capable of thriving amidst changing market demands.

Measuring the Impact: 30% Productivity Gains Explained

In the quest for increased productivity within the manufacturing sector, the application of harness solutions is proving to be a game changer, with potential gains of up to 30%. These solutions leverage advanced technologies, including artificial intelligence, to streamline processes and optimize resource allocation. By measuring specific performance metrics, manufacturers can quantify the impact of these innovations on operational efficiency, revealing how targeted interventions can lead to significant improvements in output.

Recent findings highlight that AI is already driving substantial productivity enhancements across various industries. Projections suggest that the integration of AI could augment GDP growth by 1.5% by 2035, with even more pronounced effects anticipated in the following decades. Notably, organizations utilizing AI tools report productivity boosts of 30-50% in software development and measurable increases in employee output. As manufacturing firms adopt similar technologies, the potential for a 30% productivity gain becomes increasingly realistic, setting the stage for a new era of efficiency and profitability.

Unlocking Efficiency: Boosting Productivity in Manufacturing

Overcoming Resistance to Change in Manufacturing Environments

In manufacturing environments, overcoming resistance to change is crucial for implementing innovative solutions that can enhance productivity. Employees often perceive new technologies or processes as threats to their established routines. Therefore, it is essential to foster a culture that embraces change rather than fears it. By involving staff in the decision-making process and providing clear communication about the benefits of new initiatives, companies can reduce anxiety and build a sense of ownership among their team members.

Training and support play a pivotal role in easing this transition. When employees are equipped with the knowledge and skills necessary to utilize new solutions effectively, their confidence grows, and resistance diminishes. This can lead to a smoother integration of productivity-boosting strategies, enabling manufacturers to realize substantial gains. Furthermore, highlighting success stories within the organization can inspire others to adapt and innovate, creating a more agile and responsive workforce ready to meet the demands of a rapidly evolving industry.

Unlocking Efficiency: How Harness Solutions Can Boost Productivity by 30% in Manufacturing - Overcoming Resistance to Change in Manufacturing Environments

| Factory Location | Current Productivity (%) | Projected Productivity with Solutions (%) | Increase in Productivity (%) | Challenges Faced |

|---|---|---|---|---|

| Factory A | 60 | 78 | 30 | Employee Resistance |

| Factory B | 55 | 71 | 29 | Technology Adaptation |

| Factory C | 70 | 91 | 30 | Management Resistance |

| Factory D | 65 | 83 | 28 | Training Issues |

| Factory E | 75 | 95 | 27 | Cultural Resistance |

Case Studies: Successful Integration of Harness Solutions in Industry

Manufacturing industries are increasingly turning to Harness Solutions to drive efficiency and productivity. A recent report by McKinsey & Company indicates that companies incorporating advanced technological solutions see productivity gains of 25% to 30%. For instance, a leading automotive manufacturer integrated a Harness Solution that streamlined its supply chain processes. This integration enabled real-time data analysis, reducing lead times by 20% and decreasing production costs by 15%, significantly enhancing overall operational efficiency.

Moreover, a case study on a consumer electronics firm revealed that after implementing Harness Solutions, they experienced a 35% reduction in machine downtime thanks to predictive maintenance capabilities. This not only optimized resource allocation but also improved product quality, leading to a notable increase in customer satisfaction ratings. In a survey conducted by Deloitte, 60% of manufacturers using such technology reported enhanced flexibility in their operations, illustrating how successful integration of Harness Solutions can transform the manufacturing landscape.

Related Posts

-

Exploring Innovative Harness Wire Alternatives for Enhanced Connectivity Solutions

-

Top Strategies for Optimizing Wire Assembly Processes for Maximum Efficiency

-

How to Choose the Right Wire Harness Manufacturing Service for Your Project

-

How to Choose the Right Assembly Wire for Your Specific Project Needs

-

Innovative Harness Assembly Solutions for Enhanced Efficiency and Performance

-

Innovative Wire Harness Solutions Spotlighted at 2025 China 138th Canton Fair

Toll Free: (888) 802-2505

Phone: (256) 845-1255 or (256) 845-4493

Fax: (256) 845-1321 or (256) 845-4468

© 2025 Heritage Wire Harness, LLC