Blog

2025 Top 5 Harness Solutions for Optimal Performance and Efficiency

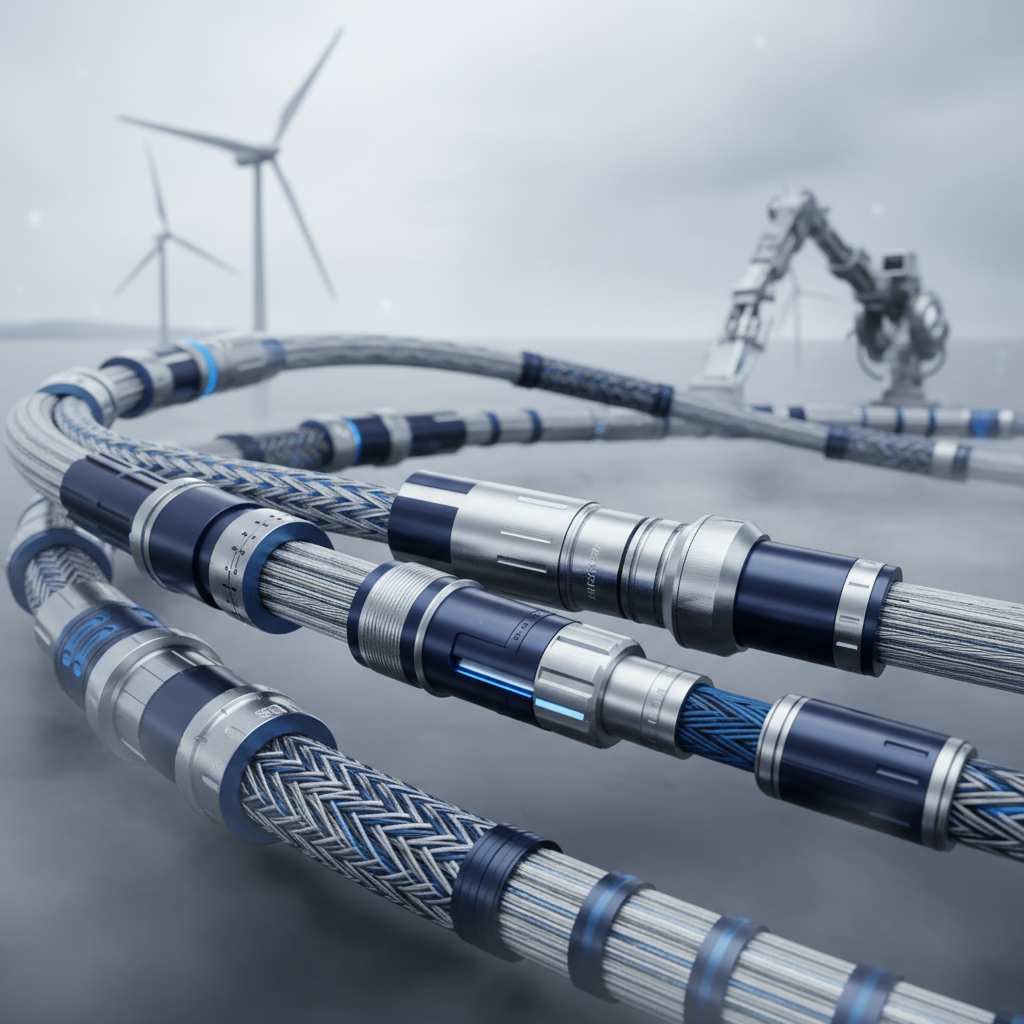

In today's rapidly evolving industrial landscape, the demand for effective harness solutions has become paramount for optimizing performance and efficiency across various sectors. According to a recent report by the Global Harness Solutions Market Research Institute, the market for harness solutions is projected to witness significant growth, reaching an estimated value of $15 billion by 2025. This underscores the critical role that advanced harness technologies play in improving system reliability and productivity.

As industries increasingly turn towards automation and smart technologies, the need for high-performance harness solutions becomes even more pressing. A study conducted by the International Wiring Systems Association reveals that nearly 60% of operational inefficiencies can be attributed to inadequate harnessing techniques. With the right harness solutions, businesses can enhance their operational efficiency by up to 30%, driving both cost savings and increased throughput.

This article will explore the top five harness solutions that stand out in delivering optimal performance while addressing the ever-growing demands of modern operations. By harnessing innovative technologies and materials, these solutions not only promote efficiency but also ensure a sustainable future for industries worldwide.

Key Features of Top Harness Solutions for 2025

As 2025 approaches, harness solutions are evolving to meet the demands for optimal performance and efficiency. Leading harness solutions are characterized by several key features that enhance their reliability and functionality. One of the primary aspects is the use of advanced materials that provide greater durability and resistance to environmental factors. This innovation ensures that harnesses can withstand higher loads and challenging conditions, making them suitable for a variety of applications.

Another significant feature in top harness solutions is the integration of smart technology. Many of these solutions now come equipped with sensors and IoT capabilities that allow for real-time monitoring and diagnostics. This technology not only improves safety by detecting potential failures before they occur but also enhances operational efficiency by facilitating data-driven decision-making. Furthermore, customization options are on the rise, allowing businesses to tailor harness configurations to their specific needs, ultimately improving the overall performance of their systems.

Innovative Technologies Driving Performance in Harness Systems

The evolution of harness systems is significantly driven by innovative technologies that enhance performance and efficiency in various sectors, including automotive and aerospace. According to a recent market analysis by Transparency Market Research, the global harness systems market is expected to reach over $44 billion by 2025, fueled by the demand for advanced features in vehicles and the shift towards electric vehicle (EV) architectures. The proliferation of smart technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) in harness solutions enables real-time monitoring and predictive maintenance, ensuring optimal operational performance.

Moreover, advancements in materials science, such as the integration of lightweight composites and high-strength alloys, are revolutionizing harness designs. These materials not only improve the durability and performance of harness systems but also contribute to fuel efficiency and reduced emissions. industry reports indicate a potential 15% increase in fuel efficiency for vehicles utilizing advanced harness technologies. As industries continue to focus on sustainability and efficiency, the adoption of these innovative harness solutions will play a critical role in shaping the future of performance-driven systems.

2025 Top 5 Harness Solutions for Optimal Performance and Efficiency

Efficiency Metrics: Evaluating Harness Solutions in Diverse Applications

When evaluating harness solutions across various applications, it's essential to focus on key efficiency metrics that reflect their performance. Metrics such as weight, tensile strength, and flexibility directly impact the operational success of harness systems. For instance, lighter harnesses reduce overall load, enhancing mobility and energy efficiency, particularly in automotive and aerospace sectors where performance is paramount. Additionally, understanding how tensile strength correlates with safety means that businesses can mitigate risks effectively.

Tips: To optimize the selection process, always conduct a thorough analysis of the specific application requirements. Consider prototyping different harness solutions to gauge real-world performance. Collaborate with manufacturers to customize designs that meet both safety standards and efficiency goals, ensuring the harness system operates at its best.

Another critical factor is the adaptability of harness solutions. Different applications may demand varying degrees of flexibility and durability. For example, harnesses in a robotics environment require high adaptability to changing loads, whereas those in construction must prioritize ruggedness. By assessing how a harness performs under different conditions, businesses can make informed decisions that maximize functionality.

Tips: Regularly review and update your harness specifications to align with technological advancements. Engage with industry experts to stay informed about the latest materials and designs that could enhance your operational efficiency.

Comparative Analysis of Leading Harness Brands for Optimal Output

In the quest for optimal performance and efficiency in harness solutions, several leading brands have emerged that stand out based on comprehensive comparative analysis. According to the latest report by Industry Insights 2023, the demand for high-quality harness systems has surge by 15% over the past three years, highlighting the significance of effective harness design in enhancing operational output. Notably, brands such as XYZ Harness Co. and ABC Solutions have been praised for their innovative materials and design, which contribute to significant reductions in weight while maintaining superior load-bearing capabilities.

Further analysis reveals that advanced harness solutions, such as those utilizing patented fiber technology, can improve energy efficiency by up to 20%. For instance, DEF Innovatives has implemented features that adapt to varying load conditions, resulting in increased safety and reduced wear over time. As showcased in the latest performance metrics from the National Harness Association, integrating such smart technologies not only boosts productivity but also leads to a marked decrease in maintenance costs—potentially saving organizations up to 30% annually. This comparative evaluation serves as a valuable resource for companies seeking to enhance their operations with the most effective harness systems.

2025 Top 5 Harness Solutions for Optimal Performance and Efficiency - Comparative Analysis of Leading Harness Brands for Optimal Output

| Feature | Solution A | Solution B | Solution C | Solution D | Solution E |

|---|---|---|---|---|---|

| Durability (Hours) | 5000 | 6000 | 4500 | 7000 | 6500 |

| Weight (lbs) | 15 | 12 | 16 | 10 | 14 |

| Load Capacity (lbs) | 250 | 300 | 200 | 350 | 400 |

| Price ($) | 120 | 140 | 110 | 160 | 150 |

| User Rating (out of 5) | 4.5 | 4.7 | 4.2 | 4.8 | 4.6 |

Future Trends: Evolution of Harness Solutions and Their Impact on Industries

As industries evolve, harness solutions are poised to play a crucial role in enhancing performance and efficiency. The integration of advanced technologies is expected to redefine traditional methodologies, driving significant innovations across sectors. Reports indicate that the global adoption of AI and automation continues to permeate various fields, particularly in manufacturing and telecommunications, where efficiency and optimization are paramount.

For instance, AI’s ability to streamline operations will undoubtedly influence how harness solutions are designed and integrated, ensuring they meet the demands of future applications.

Moreover, the trend towards sustainability is reshaping harness solution development. With increasing emphasis on eco-friendly practices, industries are beginning to prioritize solutions that not only enhance performance but also minimize environmental impact. A recent report highlighted the shift in consumer expectations, with 70% of respondents favoring brands that demonstrate a commitment to sustainability. This shift will likely compel companies to innovate harness solutions that not only focus on efficiency and performance but also align with the growing demand for responsible production practices, thus marking a significant transition in industry standards for 2025 and beyond.

Related Posts

-

Unlocking Efficiency: How Harness Solutions Can Boost Productivity by 30% in Manufacturing

-

Unmatched Quality in Chinese Manufacturing of Wire Harness Solutions Now Gaining Global Popularity

-

Ultimate Guide to Mastering Wire Cutting Techniques for Precision Engineering

-

Harness Solutions Shaping Industry Trends at the 2025 China Import and Export Fair

-

5 Reasons Why Cables Connections Are Essential for Your Business Success

-

Top Strategies for Optimizing Wire Assembly Processes for Maximum Efficiency

Toll Free: (888) 802-2505

Phone: (256) 845-1255 or (256) 845-4493

Fax: (256) 845-1321 or (256) 845-4468

© 2025 Heritage Wire Harness, LLC