Blog

Exploring Innovations in Wire Harness Fabrication: Tips for Modern Manufacturing Success

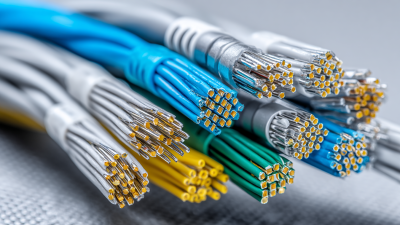

In the ever-evolving landscape of modern manufacturing, the significance of wire harness fabrication cannot be overstated. As industries increasingly rely on sophisticated electronic systems, the demand for high-quality, efficient wire harness solutions has skyrocketed. According to a recent report by Market Research Future, the global wire harness market is projected to reach USD 78.5 billion by 2025, growing at a CAGR of 8.10%. This growth underscores the critical role that innovations in wire harness fabrication play in keeping pace with technological advancements across various sectors, from automotive to aerospace.

Industry expert Dr. Emily Tran, a leader in electrical engineering at Tech Innovations Group, emphasizes the importance of adapting to contemporary challenges: “The future of wire harness fabrication hinges on integrating automated processes and sustainable practices to meet the increasing demand for performance and efficiency.” As manufacturers seek to optimize their production lines, embracing automation, advanced materials, and lean methodologies has become essential for success.

Exploring innovations in wire harness fabrication not only enhances productivity but also contributes to the development of more reliable and sustainable products. By leveraging cutting-edge technologies and best practices, manufacturers can position themselves to thrive in a competitive market, ensuring that they meet the dynamic needs of their customers while driving industry progress.

Leveraging Advanced Technologies for Streamlined Wire Harness Production

As manufacturers strive for efficiency and quality, leveraging advanced technologies in wire harness production has become imperative. According to a report by MarketsandMarkets, the global wire harness market is expected to grow from USD 62.6 billion in 2023 to USD 87.9 billion by 2028, highlighting the increasing demand for efficient manufacturing processes. Implementing automation and smart technologies can significantly reduce production time and minimize errors. Techniques such as 3D modeling and digital twin simulations allow manufacturers to optimize design processes before physical production begins, resulting in cost savings and improved product integrity.

Adopting Industry 4.0 practices is also crucial for modern wire harness fabrication. A survey conducted by McKinsey indicates that up to 70% of manufacturers have begun integrating IoT solutions into their operations. These technologies enable real-time monitoring of the assembly line, ensuring that any deviations from the production plan are promptly addressed. Additionally, using data analytics helps in predicting equipment failures and maintenance needs, which further streamlines operations. The integration of these advanced technologies not only enhances productivity but also empowers manufacturers to meet the evolving demands of various industries, including automotive and aerospace.

Exploring Innovations in Wire Harness Fabrication: Tips for Modern Manufacturing Success

| Technology | Description | Impact on Production | Adoption Rate (%) |

|---|---|---|---|

| Automated Wire Cutting | Precision cutting of wire using automated machines. | Increases accuracy and reduces waste. | 75% |

| 3D Printing of Connectors | Using 3D printing technology to create custom connectors. | Reduces lead time for custom parts. | 60% |

| Laser Marking | Permanent marking of wires for traceability. | Enhances identification and inventory management. | 80% |

| Robotics Assembly | Utilization of robots for assembly line tasks. | Improves speed and consistency in assembly. | 50% |

| IoT Integration | Applying IoT for real-time monitoring of production. | Optimizes maintenance and reduces downtime. | 40% |

Implementing Automation: Boosting Efficiency in Wire Harness Fabrication

In the rapidly evolving field of wire harness fabrication, the implementation of

automation technologies has become a cornerstone of modern manufacturing success.

A recent report by MarketsandMarkets predicts that the global market for automated manufacturing solutions is expected to reach

USD 200 billion by 2025, driven by the need for efficiency and precision. Automation not only reduces

labor costs but also minimizes human error, thereby enhancing product quality and

delivery times.

To fully leverage the advantages of automation in wire harness fabrication, manufacturers should consider integrating advanced

machinery such as automated cutting and crimping machines. These innovations can improve production speed by up to

30% and ensure tighter tolerances, vital in industries like automotive and aerospace where

safety is paramount. Additionally, the adoption of robotics in repetitive tasks allows for

greater flexibility and adaptability to changing manufacturing demands.

Tips: First, engage in thorough training for staff to operate and maintain automated systems

effectively. Second, invest in software that synchronizes automated processes across the production line, ensuring that all machinery

works in harmony without bottlenecks. Lastly, regularly analyze production data to identify areas for further automation and continuous

improvement, ensuring sustained efficiency gains in the wire harness fabrication process.

Sustainable Practices in Wire Harness Manufacturing: A Modern Approach

Sustainable practices are transforming wire harness manufacturing, making it essential for manufacturers to adopt environmentally friendly approaches. According to a recent report by the International Wire and Cable Association, the shift towards sustainable materials in wire harness fabrication can reduce waste by up to 30%, significantly lowering production costs and environmental impact. By utilizing recyclable materials and energy-efficient processes, manufacturers not only enhance their corporate responsibility but also appeal to a growing market of environmentally conscious consumers.

To successfully incorporate sustainable practices, manufacturers can follow these tips: First, invest in research and development for alternative materials such as biodegradable plastics and recycled metals. This not only improves sustainability but also enhances product durability. Second, streamline production processes by implementing lean manufacturing techniques to minimize waste and improve efficiency. Implementing real-time monitoring systems can also help in tracking material usage and identifying areas for waste reduction.

By embracing these modern and sustainable approaches, wire harness manufacturers can stay competitive in an evolving market while contributing to a healthier planet. The integration of innovative practices not only meets regulatory demands but also promotes long-term profitability through improved efficiency and customer loyalty.

Quality Control Innovations: Ensuring Excellence in Wire Harness Production

In the realm of wire harness production, quality control innovations are crucial for ensuring excellence in the manufacturing process. Recent advancements have highlighted the significance of precision engineering, which not only enhances product reliability but also aligns with the evolving demands of modern electric vehicle (EV) markets. As manufacturers like those increasing their aluminium production capacity emphasize the critical nature of high-quality components, it becomes evident that the integration of meticulous quality assurance processes is essential. A recent report indicates that manufacturers who invest in state-of-the-art quality control systems experience up to a 30% reduction in defects, ultimately saving costs and enhancing customer satisfaction.

Moreover, the shift towards sustainable manufacturing practices has spurred the adoption of advanced technologies in wire harness fabrication. Industry experts suggest that employing automated inspection technologies can elevate quality assurance measures, significantly improving productivity and reducing waste. As the demand for electric wire harnesses grows, particularly in the context of India’s booming electric vehicle landscape, manufacturers are urged to embrace these innovations. By leveraging new tools and techniques, businesses can not only secure a competitive edge but also contribute to a more efficient and sustainable manufacturing ecosystem.

Utilizing Data Analytics for Enhanced Decision-Making in Manufacturing Processes

In contemporary wire harness fabrication, data analytics plays a pivotal role in enhancing decision-making processes. By leveraging advanced analytics tools, manufacturers can gain insights into production efficiency, resource allocation, and potential bottlenecks in the workflow. This data-driven approach allows teams to make informed decisions that optimize both time and materials, ultimately leading to improved overall performance.

Additionally, the integration of real-time data analytics fosters a culture of continuous improvement within manufacturing environments. Manufacturers can track key performance indicators (KPIs) and utilize predictive modeling techniques to foresee issues before they escalate. This proactive stance not only mitigates risks but also streamlines operations, resulting in higher productivity and reduced costs. As the industry increasingly embraces these innovations, the reliance on data for decision-making becomes essential for maintaining a competitive edge in wire harness fabrication.

Related Posts

-

Exploring Innovative Harness Wire Alternatives for Enhanced Connectivity Solutions

-

Ultimate Guide to Mastering Wire Cutting Techniques for Precision Engineering

-

Understanding the Importance of Wire Harness Solutions in Modern Technology

-

Innovative Harness Assembly Solutions for Enhanced Efficiency and Performance

-

Innovative Wire Harness Solutions Spotlighted at 2025 China 138th Canton Fair

-

Innovative Techniques for Streamlined Wire Harness Production

Toll Free: (888) 802-2505

Phone: (256) 845-1255 or (256) 845-4493

Fax: (256) 845-1321 or (256) 845-4468

© 2025 Heritage Wire Harness, LLC