Blog

Understanding Harness Assembly: Essential Tips for Safe and Efficient Usage in Various Applications

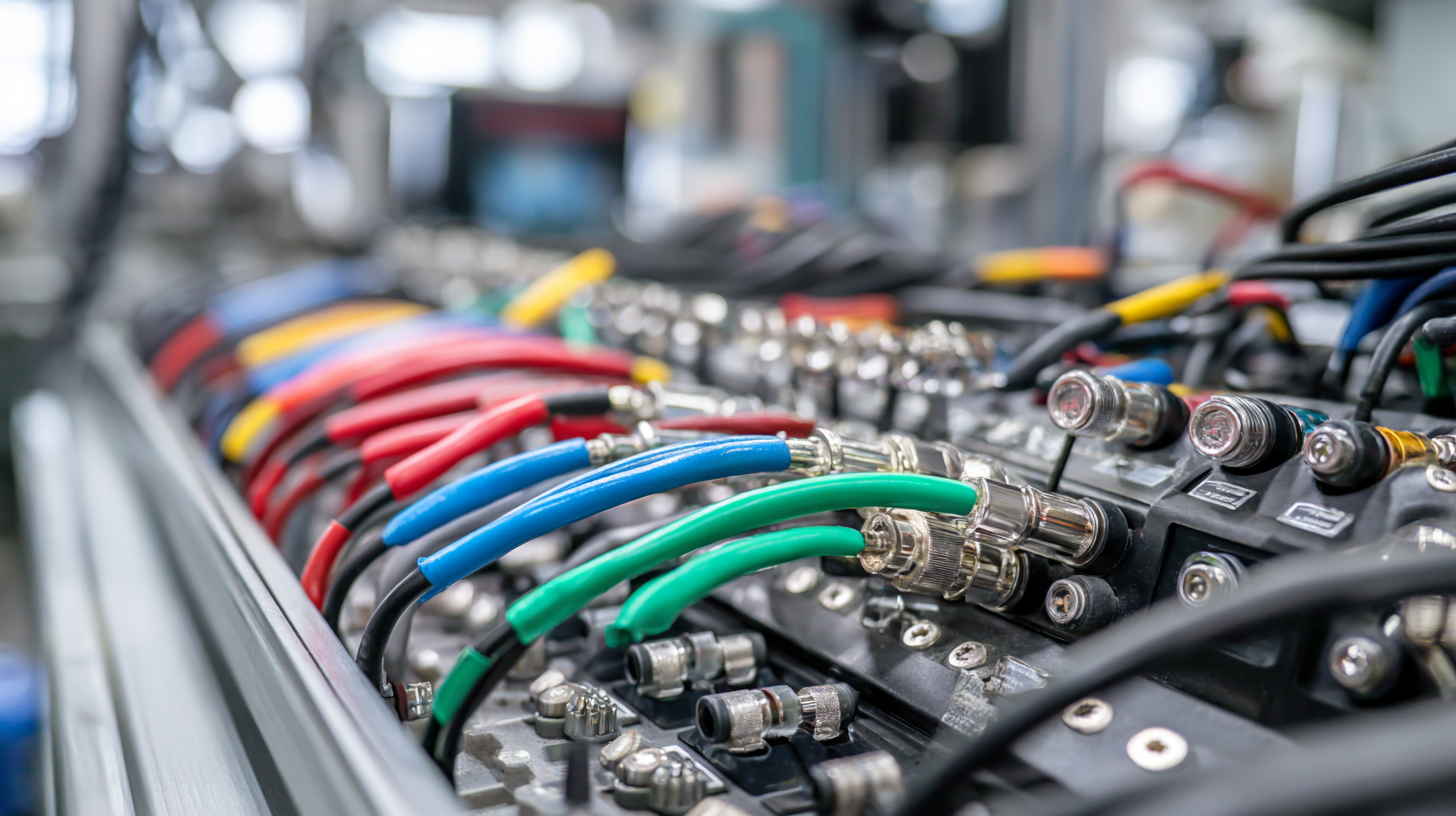

In the realm of modern engineering and manufacturing, the significance of harness assembly cannot be overstated. Whether it's for automotive, aerospace, or industrial applications, understanding the intricacies of harness assembly is crucial for ensuring both safety and efficiency. This article aims to provide a comprehensive guide on how to effectively assemble harnesses, highlighting essential tips and techniques that cater to various applications. From selecting the right materials to following best practices during installation, mastering these aspects will not only enhance the performance of your systems but also minimize potential hazards. By leveraging the insights shared herein, you can optimize your harness assembly processes and contribute to the overall success of your projects.

How to Choose the Right Harness Assembly for Your Specific Application

Choosing the right harness assembly is crucial for ensuring safety and efficiency in various applications, from industrial settings to recreational activities. According to a report by the Occupational Safety and Health Administration (OSHA), improper harness selection can lead to a significant increase in workplace accidents, with harness-related falls accounting for nearly 30% of all fall fatalities. Therefore, understanding the specific requirements of your application is essential when selecting a harness assembly.

When evaluating harness assemblies, consider factors such as weight capacity, comfort, and the environment in which you'll be operating. For example, a study conducted by the American National Standards Institute (ANSI) indicates that specific harness designs can reduce user fatigue by up to 40%. Additionally, make sure to select harnesses that are compliant with industry standards, ensuring that they have met rigorous safety protocols.

Tips:

- Always prioritize harnesses that have been tested for the specific type of work environment you are dealing with, like construction or climbing.

- Regularly inspect your harness for wear and tear, as compromised materials can significantly decrease safety.

How to Properly Inspect and Maintain Harness Assemblies for Safety

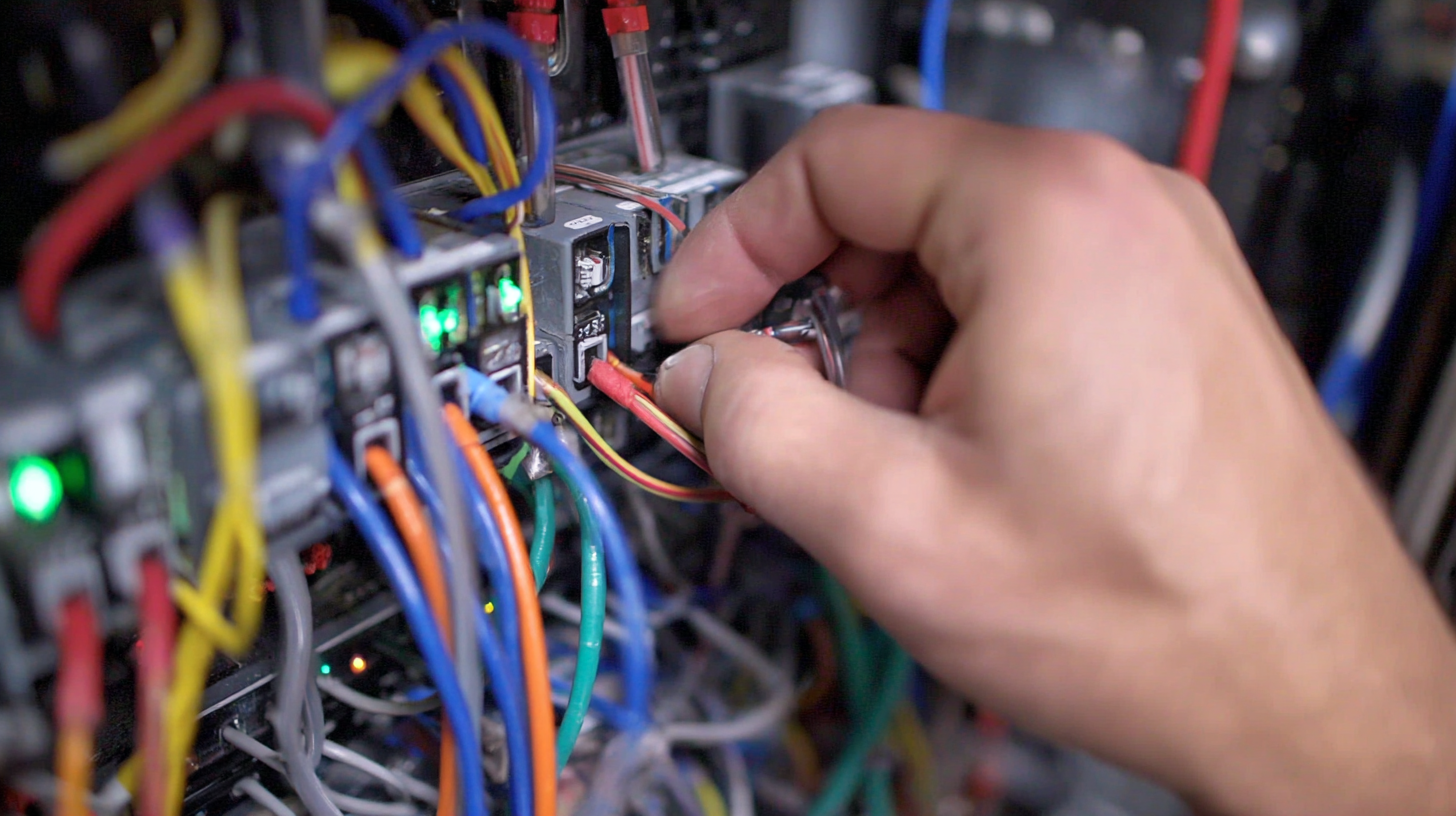

Proper inspection and maintenance of harness assemblies are crucial to ensure safety in various applications. Regular checks should be integrated into your routine to identify any signs of wear or damage. Inspect straps for fraying, buckles for cracking, and ensure that all connection points are secure and functioning correctly. Furthermore, follow the manufacturer’s guidelines for cleaning and storing harnesses to prolong their life and maintain their integrity.

Tips for inspection include performing a detailed visual assessment of the entire harness before each use. Look for deformations or discolorations that may indicate stress. Additionally, if your harness has a load-bearing capacity, ensure that it has not been subjected to forces beyond its limits, as this could compromise its safety. Employ a systematic approach by documenting each inspection, noting any issues, and addressing them promptly.

Maintenance is just as vital; always ensure that your harnesses are clean and dry after use. Store them in a cool, dry place away from direct sunlight and harsh chemicals. Familiarize yourself with the specific maintenance requirements for your harness type. Some may require periodic professional inspections, while others might just need careful user checks during regular usage. Keeping these considerations in mind will enhance safety and efficiency in any application where harness assemblies are utilized.

Understanding Harness Assembly: Essential Tips for Safe and Efficient Usage in Various Applications - How to Properly Inspect and Maintain Harness Assemblies for Safety

| Aspect | Description | Frequency of Inspection | Maintenance Actions |

|---|---|---|---|

| Webbing Condition | Check for fraying, cuts, or discoloration. | Before each use | If damaged, replace immediately. |

| Hardware Integrity | Inspect buckles, D-rings, and connectors for rust or wear. | Weekly | Clean and lubricate; replace if faulty. |

| Stitching Quality | Look for loose or missing stitches. | Monthly | Repair or replace if compromised. |

| Storage Conditions | Ensure harness is stored away from direct sunlight and moisture. | Every use | Store in a cool, dry place. |

| User Training | Ensure all users are trained in harness use and inspection. | Annually | Provide refresher training as needed. |

How to Safely Attach and Remove Harness Assemblies for Maximum Efficiency

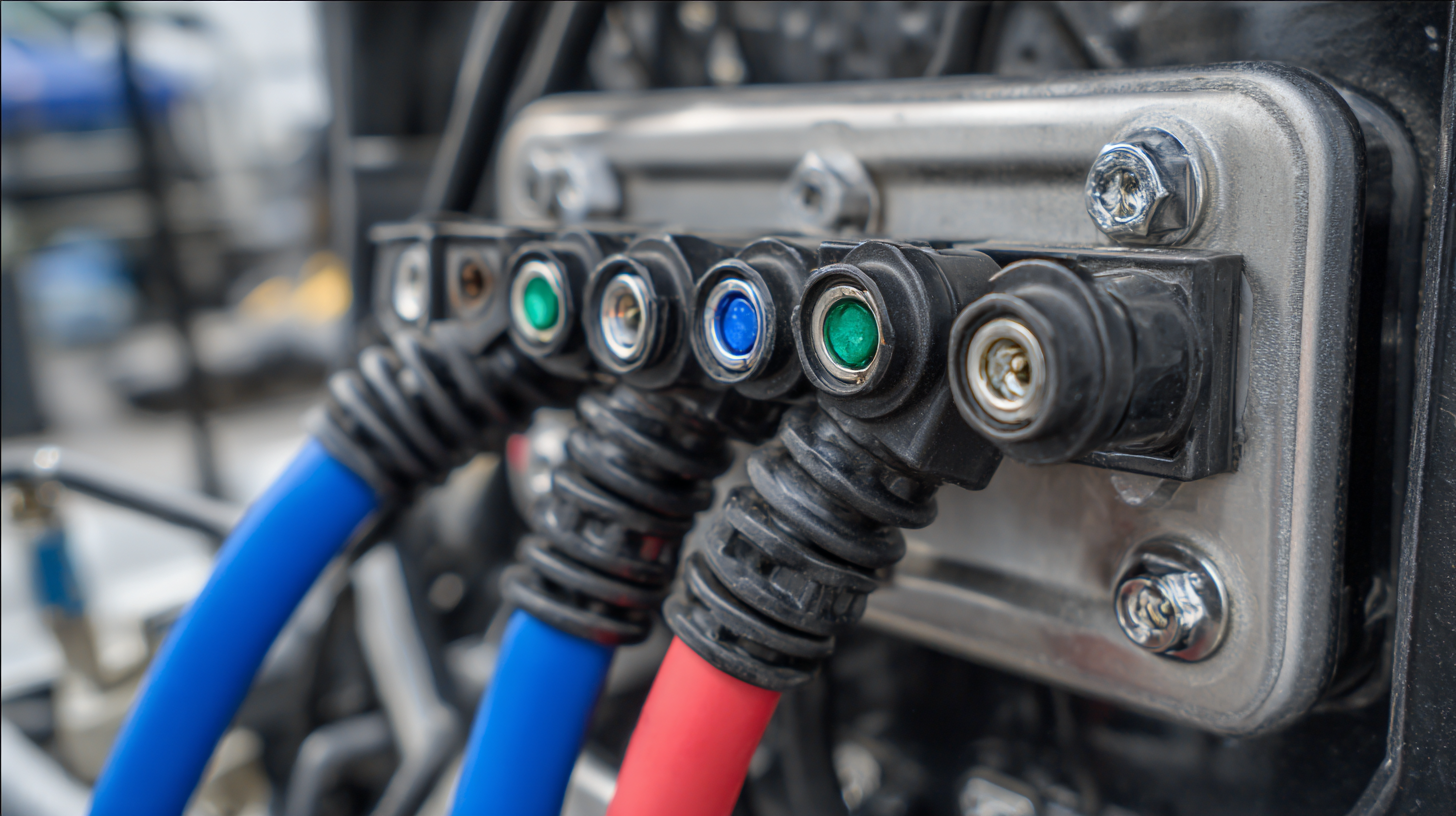

When working with harness assemblies, the process of safely attaching and removing them is crucial to ensure operational efficiency and prevent accidents. Begin by inspecting the harness and its components for any signs of wear or damage before use. Ensure that the attachment points are clean and free from debris. When attaching the harness, follow the manufacturer's guidelines meticulously. Utilize the proper techniques, such as aligning the attachment clips or hooks correctly, to secure the harness without causing strain or misalignment.

When it's time to remove the harness, approach the process with equal caution. Release the harness in a reverse order to the attachment process to avoid confusion. Always support the assembly as you detach it, and be aware of any potential tension or movement that may occur. Clear your workspace of unnecessary items to minimize hazards and make the removal process smoother. Following these essential tips not only ensures safety but also extends the lifespan of your harness assemblies, making your operations more efficient and reliable.

How to Understand the Regulatory Standards for Harness Assembly Usage

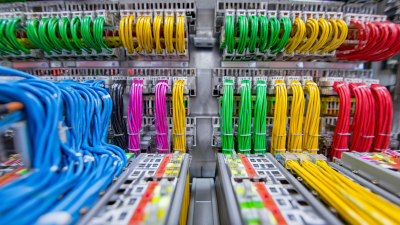

When it comes to harness assembly, understanding the regulatory standards is crucial for ensuring safety and efficiency across various applications. Regulatory bodies, such as the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI), provide guidelines that help manufacturers and users maintain compliance. These standards outline the necessary materials, testing procedures, and maintenance protocols that must be followed to guarantee the reliability of harness systems in environments where safety is paramount.

Adhering to these regulations not only protects the workers using the harnesses but also minimizes risks associated with equipment failure. It is essential to assess the specific requirements for different applications, as standards may vary depending on the industry, such as construction, aerospace, or recreational fields. By regularly reviewing and integrating the latest regulatory standards into harness assembly practices, organizations can foster a culture of safety, ensuring both legal compliance and the well-being of their workforce.

How to Train Personnel on the Correct Use of Harness Assemblies in the Workplace

Effective training on harness assemblies is crucial for ensuring worker safety and operational efficiency. With the rise of advanced tools and materials in industries, the need for structured programs that cover assembly, inspection, and safety protocols has never been more pressing. A report highlights that while 82% of HR professionals have adopted AI technologies in their workplaces, only 30% of them have received the job-specific training necessary to leverage these tools effectively. This gap suggests a significant shortfall in training that might also extend to other technical domains such as harness assembly.

In the context of harness assembly, specialized training programs like the Wire Harness Assembly for Operators (WHO) are essential. These programs are meticulously designed to equip workers with the necessary skills to handle complex tasks efficiently. Furthermore, as companies embrace AI and advanced technologies, it's vital to ensure that personnel are not only familiar with the tools but can also contextualize their use within their specific roles. Addressing these training deficits can lead to a more competent workforce that can confidently handle the demands of modern industrial environments, ultimately enhancing safety and productivity across the board.

Related Posts

-

Innovative Harness Assembly Solutions for Enhanced Efficiency and Performance

-

Unmatched Quality in Chinese Manufacturing of Wire Harness Solutions Now Gaining Global Popularity

-

How to Choose the Right Wire Harness Manufacturing Service for Your Project

-

Innovative Wire Harness Solutions Spotlighted at 2025 China 138th Canton Fair

-

Revolutionizing Connectivity: The Future of Wire Harness Solutions for Emerging Technologies

-

Harness Solutions Shaping Industry Trends at the 2025 China Import and Export Fair

Toll Free: (888) 802-2505

Phone: (256) 845-1255 or (256) 845-4493

Fax: (256) 845-1321 or (256) 845-4468

© 2025 Heritage Wire Harness, LLC