Blog

What is Harness Assembly and How Does it Work in Modern Applications

Harness assembly plays a crucial role in various modern applications, serving as the backbone for many electronic and electrical systems. As technology continues to advance, the significance of harness assembly becomes increasingly apparent across multiple industries, including automotive, aerospace, and consumer electronics. These assemblies comprise a network of wires, connectors, and terminals that work together to transmit power and signals between various components.

In today’s fast-paced world, the efficiency and reliability of harness assemblies directly impact the performance of complex systems. The integration of advanced materials and manufacturing techniques has enhanced the functionality of harness assemblies, making them more robust and adaptable to the demanding environments they encounter. As we explore the intricacies of harness assembly, it is essential to understand how these components are constructed, the technologies employed, and their functional importance in ensuring seamless operations and connectivity. Understanding harness assembly not only sheds light on its essential role in modern applications but also highlights its potential for innovation as industries seek to optimize performance and minimize downtime.

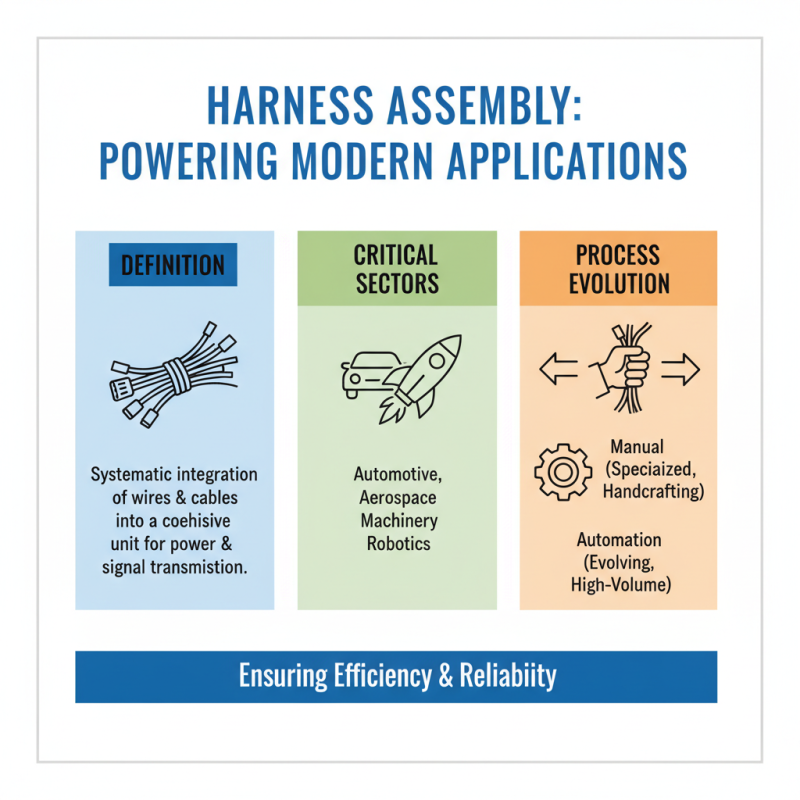

Definition and Overview of Harness Assembly

Harness assembly is a critical component in modern applications, particularly within the automotive and aerospace industries. It involves the systematic integration of various wires and cables into a cohesive unit, ensuring efficient transmission of power and signals. The evolution of harness assembly has been marked by increasing automation, yet many processes remain manual, especially in specialized sectors. For instance, while the automotive sector is making strides towards automation, certain components still require handcrafting, highlighting the intricate nature of cable harnesses.

Recent data indicate that the global automotive wiring harness market is anticipated to grow substantially, driven by advancements in electric vehicle (EV) technology and the shift towards software-defined vehicles (SDVs). With investments reaching billions in innovative manufacturing processes, the industry is addressing the complexities of harness design integration, particularly through Electronic Design Automation (EDA) tools. These tools streamline the workflow, allowing for better collaboration and efficiency in designing cable assemblies. Additionally, robot-assisted assembly techniques are being explored, especially in aerospace, where the need for precision and flexibility in small batch production remains essential. The trends suggest a future where harness assembly is increasingly optimized through technology, paving the way for smarter and more efficient manufacturing solutions.

Key Components of a Harness Assembly

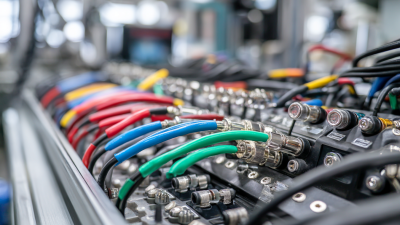

Harness assembly is a critical component in various modern applications, especially in the automotive and aerospace industries. At the core of any harness assembly are its key components, which include connectors, wires, terminals, and protective coverings. These components work in unison to facilitate the efficient transmission of electrical power and signals.

Connectors are pivotal to harness assemblies, designed to ensure secure electrical connections while minimizing resistance. Reports from the Wiring Harness Manufacturers Association indicate that the quality of connectors can affect system performance by up to 30% in complex machinery. The wires used are typically made from high-conductivity materials such as copper, which, according to industry analysis, provide optimal performance and durability under varying environmental conditions. Terminals, which connect wires to connectors, must be robust to withstand physical stress and temperature fluctuations, thereby ensuring longevity and reliability.

Protective coverings, often made from lightweight yet durable materials, serve to safeguard the internal components against contamination and physical damage. The latest industry surveys reflect a growing trend towards using environmentally friendly materials, with over 40% of manufacturers reporting shifts towards sustainable practices in harness assembly. Together, these components contribute to the overall functionality and resilience of harness assemblies in advancing technology applications.

Principles of Operation in Modern Applications

Harness assembly plays a crucial role in modern applications across various industries, particularly in automotive, aerospace, and electronics. The principles of operation for harness assemblies primarily involve the integration of multiple wires and components into a single streamlined unit. This not only enhances efficiency in manufacturing but also simplifies the installation process in numerous devices. According to a report by MarketsandMarkets, the global automotive wiring harness market is expected to reach USD 52.1 billion by 2025, illustrating the growing demand and investment in this technology.

Harness assemblies operate on the foundation of robust design and material selection, providing durability and reliability under different environmental conditions. They are often designed using advanced CAD software, ensuring that each component is precisely tailored to the specific application. Furthermore, with the incorporation of automated manufacturing techniques, the accuracy and speed of production have significantly improved. A study by Grand View Research highlights that the implementation of automation in wiring harness assembly can reduce production costs by up to 20%.

Tip: When selecting harness assemblies for your projects, consider factors such as operating temperature, mechanical strain, and environmental exposure. These parameters can affect the overall performance and lifespan of the harness. Additionally, ensure that the assembly is compliant with industry standards to maintain safety and quality in your applications.

Applications of Harness Assembly in Various Industries

Harness assembly plays a crucial role in a variety of industries, leveraging advanced technology to streamline and optimize processes. For instance, in the aerospace sector, harness assemblies are essential for connecting critical electrical systems within aircraft, ensuring reliability and safety. According to industry reports, the aerospace harness assembly market is projected to reach over $7 billion by 2026, reflecting the growing demand for innovative and efficient solutions in aerospace engineering.

In the automotive industry, harness assemblies are integral to managing complex electrical systems in vehicles. As electric and hybrid vehicles become more prevalent, the need for robust harness solutions increases. The global automotive wiring harness market is anticipated to grow at a CAGR of about 8% from 2023 to 2030. This growth underscores the shift towards electric mobility and the necessity for advanced harness designs that meet stringent safety and performance standards.

**Tips:** When designing harness assemblies, it's crucial to consider the material and layout to avoid issues such as electromagnetic interference. Additionally, implementing modular designs can enhance flexibility and repairability, which is vital in industries like aerospace and automotive. Regular testing and validation of harness designs can further mitigate risks and improve overall system performance.

What is Harness Assembly and How Does it Work in Modern Applications - Applications of Harness Assembly in Various Industries

| Industry | Application | Key Features | Benefits |

|---|---|---|---|

| Automotive | Electrical Systems | Durability, Flexibility | Increased safety, Reliability |

| Aerospace | Wiring Harness | Lightweight, Heat Resistance | Space efficiency, Enhanced performance |

| Telecommunications | Network Cabling | High-speed connectivity | Improved data transmission, Scalability |

| Renewable Energy | Solar Panel Systems | Corrosion Resistance | Longevity, Efficiency in energy harvesting |

| Consumer Electronics | Device Connections | Compact Design | Space-saving, Easy assembly |

Future Trends and Innovations in Harness Assembly Technology

Future trends in harness assembly technology are rapidly evolving, driven by advancements in automation and smart manufacturing. As industries strive for greater efficiency and precision, the integration of robotics and artificial intelligence into harness assembly processes has become essential. Automated systems are not only enhancing production speeds but also minimizing human error, thereby improving overall product quality. AI algorithms are being utilized to optimize design and assembly processes, allowing for more adaptable and versatile harness configurations tailored to specific applications.

Additionally, the emergence of Industry 4.0 is further revolutionizing harness assembly. Connected devices and the Internet of Things (IoT) enable real-time monitoring and data analysis, providing insights that can streamline operations and reduce waste. This interconnected approach facilitates predictive maintenance, ensuring that equipment remains operational and minimizing downtime.

As companies continue to embrace these technologies, the future of harness assembly holds the promise of higher levels of customization, sustainability, and efficiency, positioning it to meet the demands of increasingly complex and diverse modern applications.

Related Posts

-

Innovative Harness Assembly Solutions for Enhanced Efficiency and Performance

-

Understanding Harness Assembly: Essential Tips for Safe and Efficient Usage in Various Applications

-

Top Strategies for Optimizing Wire Assembly Processes for Maximum Efficiency

-

How to Choose the Right Assembly Wire for Your Specific Project Needs

-

How to Choose the Right Assembly Wire for Your Project Needs

-

Ultimate Guide to Mastering Wire Cutting Techniques for Precision Engineering

Toll Free: (888) 802-2505

Phone: (256) 845-1255 or (256) 845-4493

Fax: (256) 845-1321 or (256) 845-4468

© 2025 Heritage Wire Harness, LLC